Hunan Jiashan Hardware Tech as a branch company of J AND R

METALWORK,established in 2007 and located in Changsha, Hunan,

China.After almost 17 years management development and technical

improvement, Jiashan is willing to be a leading supplier in

hardware industry. Meanwhile, we are one of member of Hardware

industrial Association and Green energy industry Association.

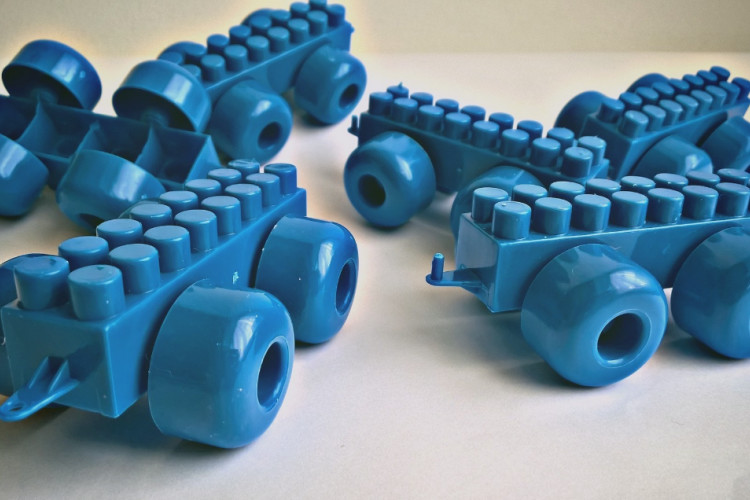

Jiashan is specialized in milling,turning,lathe 5 axis cnc

machining parts,injection molding parts,alumium extrusion

parts,laser cutting parts,sheet metal fabrication parts,wire edm

parts,vacuum casting parts and fasteners.Those parts are widely

service for electric vehicle,solar system,wind power system and

construction machinery industry.

During17 years domestic and abroad market investigation, Jiashan's

products are sold to many countries and regions including the North

America, Europe, Australia, the Middle East and Asia. With owned

the advanced cnc machinee, milling machine, polishing machine,

stamping machine etc. Jiashan is able to degsin and produce varies

OEM parts with drawings or samples provided. Further more, Jiashan

also can help to provide a whole solution for modularity R&D of

electric vehicle and solar system .

By constantly strengthening our management and consummate the

quality guarantee system.In 2023, Jiashan acquired ISO9001:2008

quality certification. Currently,the 5S management mode is

implemented in the whole Jiashan system.

Best quality and best service is and will be always our toppest

concern.